Showcasing Maker Expertise with the People and Skills Specification

- September 22, 2023

- 7 min read

To build a sustainable distributed manufacturing ecosystem that is globally networked and implemented at the local level, a combination of open infrastructure, information, processes, and data specifications needs to be developed and shared openly with the global community. During its first successful year, the mAkE project provided makerspaces, entrepreneurs, SMEs, and start-ups with open resources and tools to enable them to build sustainable businesses. The People and Skills Specification (PSS) developed during the Research phase of the project, is a powerful new way for individual makers to share their personal skills, experience and accomplishments.

Regarding this, check out the full deliverable 4.1 Skills – Mutual Recognition Standard.

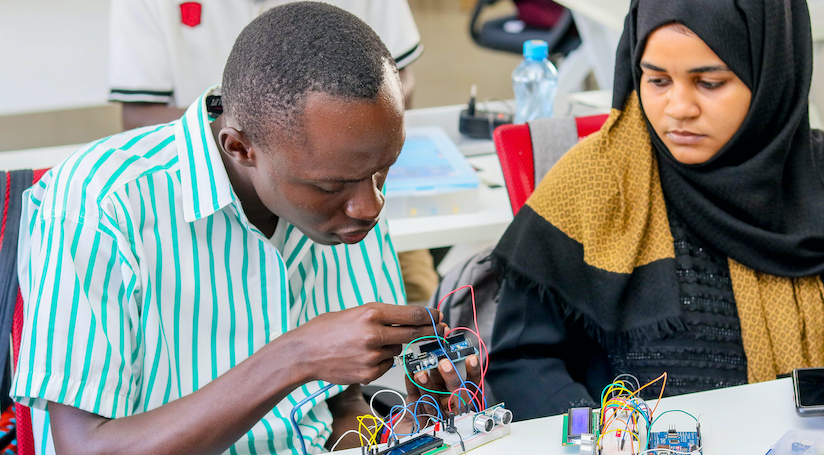

Image 01: Maker expertise shared during a workshop in the I.O.Me Innovation Labs, a humanitarian fabrication lab in Kenya and one of the sites currently testing the People and Skills Specification.

Introducing the People and Skills Specification (PSS)

Image 02: Ongoing project work in Fablab Winam, a community, open access fabrication center in Kenya, and one of the organizations currently testing the People and Skills Specification.

When it comes to producing physical goods in makerspaces, fab labs, and other manufacturing facilities, the right materials, machinery, and spaces to support production are all needed to get the job done. There are many ways to ensure that the physical resources are available for producing items; looking to resources such as the IOPA’s growing World Map of Manufacturing to see if certain facilities and machinery are available nearby, or looking to local inventories for a listing of tools and materials addresses the physical components of how something gets made – but what about the skills and knowledge needed? Sometimes it can be difficult to find the expert needed to manage the production process, especially for complex production or products that are in a testing phase or are not produced regularly in a facility. With the People and Skills Specification (PSS) there is now assurance that the experienced makers to support production can be located and matched with the right project at the right time.

“The central focus of the People and Skills Specification (PSS) is to create a shared understanding of the experience, skills, and knowledge that is needed to make things”

The PSS provides a framework for creating an individual record of experiences, skills, and relevant training and certificates that makers can use to showcase accomplishments and relevant knowledge to potential employers, peers, and collaborators across global networks. This record of skills and accomplishments can also be used to help makerspaces match makers with open product bids. The PSS addresses the critical component of knowledge-sharing for the reproducibility of items – who can provide the expertise for making things. By establishing a shared understanding and vocabulary surrounding the production of goods, we have the potential to open up networked conversations between experts in digital and physical fabrication.

Why Consider Using the People and Skills Specification?

PSS provides the potential for broadening a global network of experts, helping place the possibility of product prototyping into the hands of community members, which means increased potential for rapid collaboration, and increased overall quality of the products being produced. Increased recognition of expertise and awareness of who has this expertise also means that products being made are manufactured with fresh community knowledge and skill, which means better products for our society.

The People and Skills Specification provides potential for community, business, and individual empowerment.

The increasingly diverse engineering talent that will now have the potential to recognize local, specialized knowledge, will appeal to industry and larger manufacturing companies, which supports individual makers seeking industry jobs. Centering this understanding locally and culturally in the communities that the mAkE project supports is critical. Many community voices were included in the development of the PSS, using multiple research methods, and drawing from a wealth of global maker expertise.

Keeping Tech and Innovation Grounded in Local Communities

Establishing a shared understanding and vocabulary surrounding the production of goods is not easy; equipment, processes, and materials vary across makerspaces, and the training and certifications available and/or required to produce items vary by region, country, and continent. To create a baseline of understanding across a network as large as the mAke project’s, extensive research was conducted.

Image 03: AMN gathering in Cape Town

Workshops such as that held at the African Makerspaces Network (AMN) (shown above) event in November 2022 provided valuable community member input to supplement ongoing research on the literature regarding maker skill recognition and credentialing. Conversations about how individual makers and organizations navigate the digital fabrication and physical production spaces, and how they connect with other networks and find resources support ongoing interviews with makerspace and maker education leaders about credentialing and recognition platforms.

25 interviews were conducted with global maker community leaders involved in or leading digital maker passport program development, maker credentialing or education, following extensive research on pre-existing frameworks for recognizing maker credentials. The analysis of these interviews was used to develop a targeted survey sent to the mAkE project and connected networks.

A targeted survey received 96 responses from makerspace leaders and members across Africa and Europe, providing in-depth responses to questions on maker practices, preferences, common machinery and tools, common and desired maker competencies, and the utility of a people and skills specification applied to a digital maker passport.

Image 04: Research site visit to Gearbox in June 2023, by members of the GOSH and IOPA communities. Gearbox is a fabrication and design facility that provides co-location and training in Nairobi, Kenya, and is one of the organiszations currently testing the People and Skills Specification.

Site visits to multiple makerspaces across Africa, Europe, and North America were conducted to establish a contemporary, shared understanding of how, in an industry such as manufacturing where competencies and needs vary so much depending on region – could a shared understanding be established?

Taking community voices into account, the People and Skills Specification provides skills-based categories for recognition and credentialing that are designed for flexible customization to fit the needs of individual organizations and makers.

In addition to providing a record of personal maker skills, experiences, and accomplishments, this information can also be used as part of developing a maker passport system. An example of a successful passport program with progressive steps is the Maker Access Pass (MAP) program, where workshops and training are designed specifically to fill any knowledge or skills gaps a specific makerspace or maker network needs for production.

What Comes Next, and How to Get Involved

Work on the mAkE project’s Maker Passport and a Distributed Contracting System is continuing, integrating the PSS into a network that will engage makerspaces from Europe and Africa to be part of a new production model. Through continuing our work on an interconnected system and strong network, the day where local production that respects the environment and the values of transparency, collaboration, and fair trade is on a near horizon.

Ways to Get More Information

To keep up-to-date on the latest work and use cases related to the PSS: https://www.internetofproduction.org/people-and-skills

Join a community forum discussion between multiple global organizations on the PSS and other related projects on the Internet of Production Alliance Community Forum: ??https://community.internetofproduction.org/

Ways to Get Involved

Joining the People and Skills Working Group is a way to get involved in ongoing development of the PSS, as well as being a part of discussing tooling, education, and outreach needs surrounding the standard. Join working group members from academic and industry spaces from around the world and become a part of building a foundation for open sharing that has the potential to impact millions by getting in touch.

Testing of the PSS is currently underway, and we are always looking for more use cases where this exciting new specification could be applied. If you have ideas on use cases or want to be kept up to date on, or involved in the PSS, get in touch! Everyone is welcomed to provide feedback on the current on the current PSS signup form in development:

https://forms.gle/WBxoPHYEJNnRYoNU6

Research is ongoing, and any recommendations on platforms, organisations, or people you think should be included in this work are welcomed, get in touch: [email protected]