Journey to develop a Scalable Ugali Maker – story from the MiR

In this blogpost, read the testimonial of Witness Shangali, a dedicated member of Twende Makerspace, recently participated in the Makers-in-Residency Program at EcoCentre-Varennes-sur-Allier in France. During her time there, she developed innovative solutions like a scalable ugali maker, expanding her skills in advanced fabrication and design techniques.- November 11, 2024

- 3 min read

My name is Witness Shangali, and I am a member of Twende Makerspace. As a participant in the Makers-in-Residency Program at EcoCentre-Varennes-sur-Allier in France, I had the incredible opportunity to explore the diverse capabilities of the FabLab, such as embroidery machines, laser cutters, and 3D printers. With guidance from the team, I also learned the basics of Inkscape and SolidWorks for project design.

Through hands-on workshops like the glass workshop and wood machining, I gained a deeper understanding of essential tools and techniques. This experience enabled me to design a scalable, affordable, and user-friendly ugali maker, aimed at simplifying the preparation process for schools and restaurants.

Being immersed in a new cultural environment, I tried some French food, despite the language barrier at some point, the team made sure we understand each other. I visited historic castles, and toured nearby towns, making the residency not just a professional but also a deeply enriching personal experience.

Fig.1: Witness and the team at EcoCentre-Varennes-sur-Allier FabLab

Makerspace and Innovation

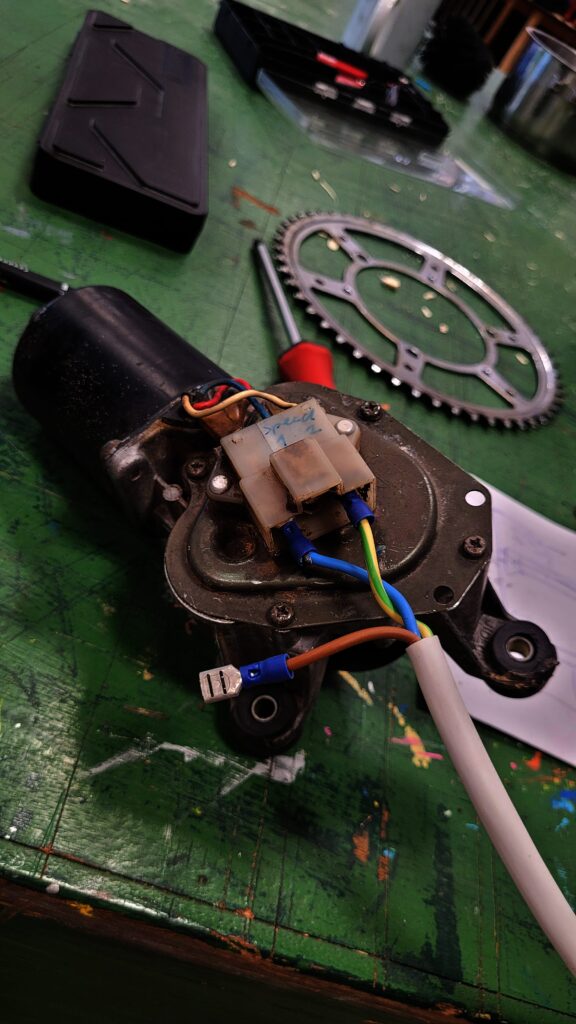

At the makerspace, I improved my skills in sketch modeling, engineering, and advanced tools like the laser cutter, CNC milling and Shaper machine. Despite initial setbacks due to the lack of detailed drawings, together with the FabLab team, we persisted in using wooden models to simulate components and continuously improve the design through iteration. The efforts, support, and guidance from the team at the Fablab culminated in a prototype featuring a motor-driven system that automates the stirring process, significantly reducing physical strain and improving efficiency.

Fig.2: Using the CNC Milling Machine

The innovation has the potential to revolutionize ugali preparation in Tanzania. With time being a limiting factor, the prototype was not completed to the testing stage. By making the ugali maker widely accessible, I aim to benefit institutions across the country, from schools to restaurants. My journey exemplifies the power of technology and creativity in addressing real-world challenges and empowering communities.

Fig.3: Working on the prototype

I’d like to express my sincere gratitude to Twende Maker Space for providing me with the opportunity to delve deeper into the project. Additionally, I’m thankful to Ecocentre in Varenne-sur-Alliers for hosting me and offering a valuable experience. Finally, I’m incredibly grateful to The Global Innovation Gathering (GIG), GreenTec Capital Africa Foundation, and mAkE Africa EU (mAke) for providing me with such an amazing opportunity that will spark the development of the project.

By Witness Shangali

Social media contacts: LinkedIn

Read the testimonials from the other MiR participants: