Developing a recycling 3D filament solution – story from the MiR

In this blog post, read the testimonial of Martine Basaninyage, who participated in the Makers-in-Residency Program at the Hackerspace Liège in Belgium. During her journey, she developed an innovative solution to recycle plastic bottles into 3D printer filament, gaining valuable skills and insights to bring sustainable technology back to Rwanda.- November 11, 2024

- 4 min read

My name is Martine Basaninyage and this year, I had the incredible opportunity to travel to Germany and Belgium to work on my recycling project, which turns plastic bottles into 3D printer filament. This journey not only helped me refine the project but also introduced me to new tools, ideas, and inspiring people working on sustainability and other engineering solutions. This program is called Makers-in-Residency and allowed to do a 1-month residency in the Hackerspace Liège in Belgium.

re:publica in Germany: Meeting Global Innovators

My trip began in Germany, where I attended the re:publica conference. It was an inspiring event that allowed me to connect with the GreenTec Capital Africa Foundation and Global Innovation Gathering (GIG) team and meet innovators from around the world. The discussions on sustainability and technology aligned perfectly with my recycling project, which aims to help schools, innovators, and entrepreneurs recycle plastic waste into usable 3D printing filament.

Hackerspace Liège: Building and Prototyping

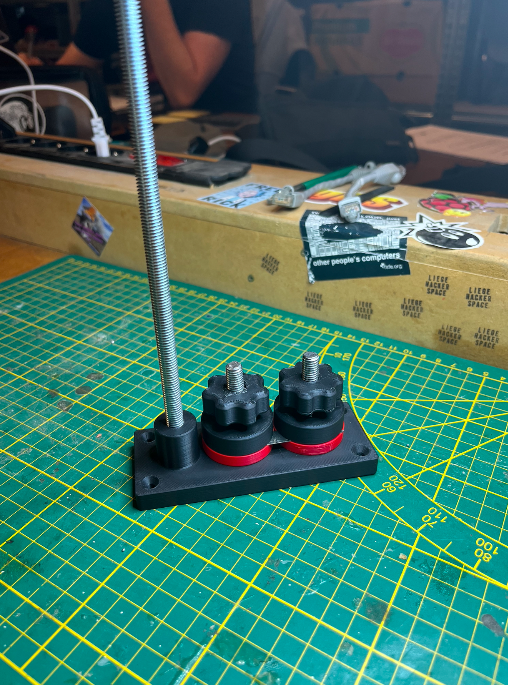

At the makerspace, I improved my skills in sketch modeling, engineering, and advanced tools like the laser cutter, CNC milling and Shaper machine. Despite initial setbacks due to the lack of detailed drawings, together with the FabLab team, we persisted in using wooden models to simulate components and continuously improve the design through iteration. The efforts, support, and guidance from the team at the Fablab culminated in a prototype featuring a motor-driven system that automates the stirring process, significantly reducing physical strain and improving efficiency.

After Germany, I travelled to Hackerspace Liège in Belgium, where the technical work on my project really took off. Hackerspace is a creative community of makers, and it was the perfect environment for me to refine and improve my recycling machine.

During my time there, I learned to use new tools like metal cutting, automated drill machines, sanding machines, and 3D modeling, which were crucial in enhancing the machine’s design. One of the most important changes we made was improving the machine’s efficiency, reducing energy consumption, and removing the coding aspect by integrating heat and speed regulator buttons, making it more practical and easier for anyone to use.

In Liège, I worked with other makers, testing the machine and making adjustments based on their feedback. By the end of my stay, we had a working prototype that was much more user-friendly and ready to be implemented in makerspaces for prototyping and schools for 3D model practice.

This machine is particularly important in Rwanda, where filament is expensive—10 grams costs around 7.30 USD, creating barriers for innovators, prototyping, testing, and students. However, recycling plastic bottles for 3D printing is free, and a 500 ml plastic bottle can produce 35 to 40 grams of filament.

Achievements and Lessons Learned

This trip allowed me to achieve several key milestones. First, we significantly improved the filament-making process, making it more accessible for schools with limited resources. I also gained hands-on experience with technologies that can be implemented in our makerspace back in Rwanda.

The most rewarding part of this journey was seeing the project come together after one month of hard work. Despite the challenges of balancing learning and building, as well as dealing with the language barrier in Liège, where French is predominantly spoken, I left Belgium with a functioning prototype and the skills to continue refining it. My goal is to make it easy to implement in creative labs, makerspaces, and local schools.During my free time, I explored some incredible places, such as the Atomium, Grand Place, Montagne de Bueren, B3, the Soviet War Memorial, Liège Aquarium, and Parc de la Boverie.

Bringing the Project to Rwanda

Now that I’m back in Rwanda, my goal is to introduce the recycling machine in schools, Makerspace Kigali, and universities. I plan to train teachers and students to make their own filament from plastic bottles, which will save costs and promote sustainability in education.

What’s next? I hope to expand this project to more schools and seek financial support to make it widely accessible. I’m excited to see how this machine can contribute to a greener, more innovative learning environment.

Recently, I also supported students from Rwanda Polytechnics in implementing their own machines for end-of-year projects, which was incredibly rewarding.

My time in Germany and Belgium was both challenging and rewarding. From meeting inspiring innovators to building a working prototype, this journey has fuelled my passion for sustainability and technology. Now, I’m focused on bringing what I’ve learned back home and continuing to make an impact through this project.

By Martine Basaninyage

Read the other testimonials from the MiR participants: